The IADC Technology Value Guide is intended to suggest positive aspects of

various types of well-construction technologies, as well as point out potential

drawbacks. In addition, each technology listed (column headers) in the TVG is

linked to separate pages containing definitions, illustrations and training

resources.

IADC encourages its members to provide feedback on the TVG, and to supply

relevant illustrations and training resources. The TVG is an evergreen document,

and IADC are open to contributions. For more information, please email

mike.killalea@iadc.org.

|

|

● |

Yes (has the ability to have this functionality) |

◐ |

Sometimes |

The IADC Technology Value Guide is intended to provide general information

regarding the positive and negative aspects of key well-construction

technologies.

|

|

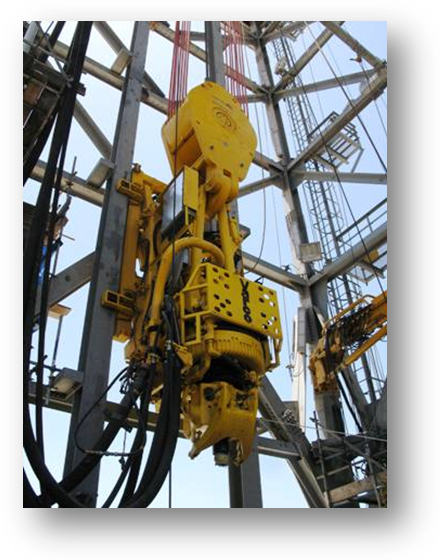

Figure 1" National Oilwell Varco (NOV) top drive. Courtesy of NOV. |

Top drive systems primarily function like a power swivel, applying rotary torque

to the drill pipe at the top of the drill string. Some early top drives are

suspended below a separate rotary swivel, while some have an integrated swivel.

The prime difference from a power swivel is the power, load rating, and ability

to connect the stand or drill string to the powered main shaft at well center

without human intervention through the use of a "pipe handler" under the top

drive. This facilitates drilling ahead with stands of drillpipe where prior to

this all connections had to be made at the drill floor which meant only one

single from the rathole could be added at a time. Top Drives are an alternative

to Kelly drive systems powered by a rotary table. Top drives also provide

improved back reaming capability to aid in pulling out of the well while

rotating. Top Drives allow both pumping and rotating during hoisting, making it

possible to pull out of a wellbore with mechanical obstructions. Additionally, a

remote kelly cock, or integrated BOP valve, is connected to the top drive main

shaft and can be remotely actuated from the driller's console. Top drives are

generally rated for hoisting loads at 150 ton, 250 ton, 350 ton, 500 ton, 750

ton, 1000 ton, and 1250 ton. A rotary table is occasionally still used for a

back-up rotation system, or as a method to turn casing in the well while adding

a joint of casing to the string to avoid potential sticking problems. In a few

cases no rotary exists and a simple device to handle the slips is put in its

place at well center on the rig floor.

Training (examples):

Aker Solutions

National Oilwell Varco

TTS Sense

|

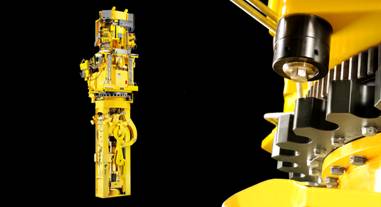

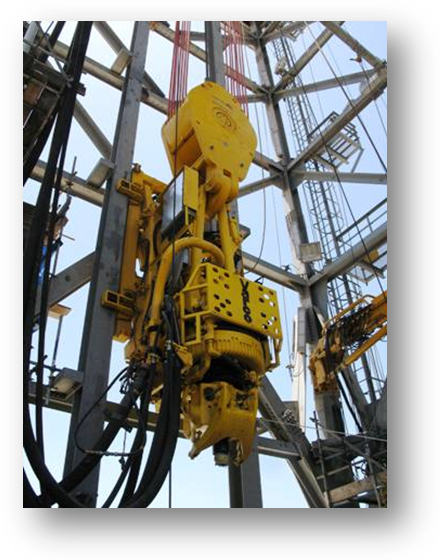

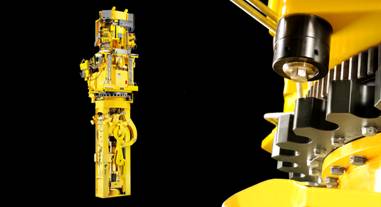

Figures

2 & 3: At bottom, Aker Solutionís MH DDM 1000 ACô

top drive. At left, Akerís MH MDDM 1000 ACô top drive. Courtesy of Aker

Solutions.

|

↑

top

|

|

Figure 4: Transocean Discoverer Enterprise. Courtesy of Transocean.

|

The use of machines to facilitate simultaneous activities in a safe manner, such

as offline standbuilding while drilling ahead and running a BOP in deepwater

operations while drilling tophole. The challenge associated with multi-activity

operations usually includes number of operators required as well as safety

systems to manage potential interference between machinery and personnel. |

↑

top

|

|

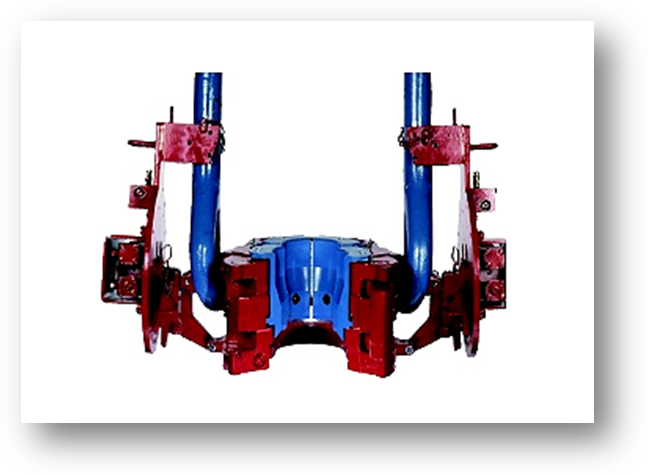

Figure 5: NOV PS-30 Power Slips. Courtesy of

NOV. |

Slips: Wedge-shaped pieces of metal with serrated inserts (dies) or other

gripping elements, such as serrated buttons, that suspend the drill pipe or

drill collars in the master bushing of the rotary table when it is necessary to

disconnect the drill stem from the kelly or from the top-drive unitís drive

shaft. Rotary slips fit around the drill pipe and wedge against the master

bushing to support the pipe. Drill collar slips fit around a drill collar and

wedge against the master bushing to support the drill collar. Power slips are

pneumatically or hydraulically actuated devices that allow the crew to dispense

with the manual handling of slips when making a connection. |

↑

top

|

|

Figure 6: NOV BX-4-75 Power Elevator. Courtesy

of NOV. |

These are air or hydraulic elevators operated on bails hanging below the

traveling equipment, which provide a remote opening and closing of the elevator

without human intervention. |

↑

top

|

|

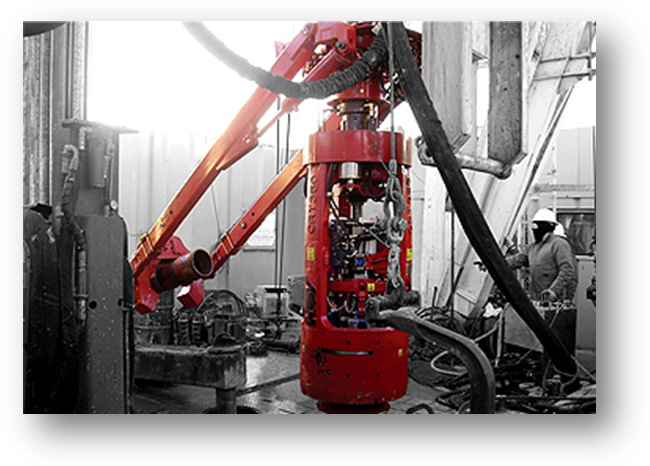

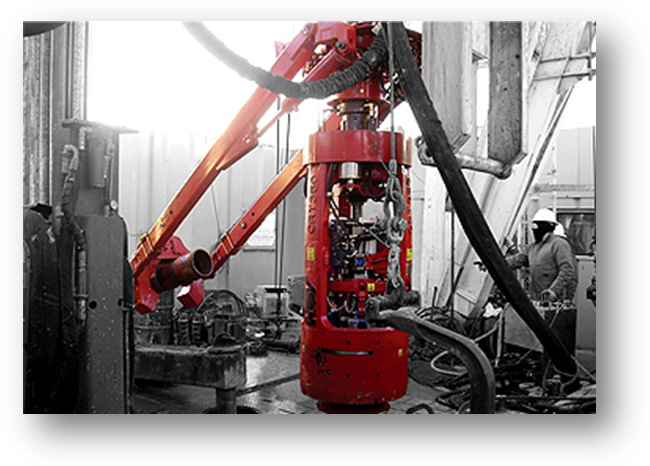

Figure 7: Canrig mechanized roughneck. Courtesy

of Canrig. |

A machine that integrates the function of a spinning wrench and a torque wrench

to make up and break out drill pipe connections. These machines evolved to

replace manual connections and increase the safety of making and breaking

connections by eliminating the manual handling involved with suspended

individual tools. The machine may be configured as a single wire hung device or

as an arm-deployed or floor rail-mounted device to facilitate the continual

hydraulic movement of the machine in and out from a well center, mousehole, and

in some cases the rathole location. Some larger machines incorporate pipe thread

doping and cleaning systems, bit breakers, mud buckets and full remote control

and/or automated operations. Some machines adapt to connect casing tong

mechanisms and some cover a full range of tubular and casing up to 20Ē.

Training:

|

|

|

Figure 8: TTS Energy Multifunctional Roughneck. Courtesy of TTS Energy.

|

Functionally replaces the derrickman in guiding pipe from the set-back to the

travelling equipment. Some systems have hoist mechanisms and some work in

conjunction with an intermediate and lower arm. These machines are remote

controlled or operate in semi- or fully-automated mode from a derrick mounted

station/cabin or a floor mounted station/cabin or a driller's station integrated

control system. |

↑

top

A two arm system is the combination of an upper tailing arm and an intermediate

hoisting/racking arm. A three arm system is the combination of a two arm system

and a lower racking arm often added to aid in stability of handling drillpipe on

a floating vessel, and some systems also use the lower racking arm as a riser

tailing device. Each arm (in most cases) is independently controlled in a

separate cabin or control station. Usually the arms are hydraulic systems used

in conjunction with an air or hydraulic-operated latched fingerboard.

Upper Tailing Arm: A heavy duty guide arm used as an upper racking arm to

replace the derrickman's function of manually moving stands of drill pipe from

the fingerboard to the elevators and back. It does not hoist the stand. The

upper tailing arm is usually installed underneath the diving board between the

fingerboards and operated by a man standing on the diving board or standing on

the drill floor. Generally used on land rigs or smaller jack up offshore rigs

where there is no to limited rig motion

Intermediate Racking Arm: Usually the hoisting mechanical device in a two or

three arm pipehandling system connected to the derrick in the middle of the

set-back, guiding the center of a drilling stand between the set back stored

position and the well center. The arm is usually controlled locally or

integrated in an automated or semi-automated system ran from the drill floor or

in the driller's cabin.

Lower Racking Arm: Primarily a guide arm often used as a second or third arm in

a pipehandling system. The arm is usually controlled locally or integrated in an

automated or semi-automated system ran from the drill floor or in the drillerís

cabin.

Lower Tailing Arm: A heavy duty guide arm. Sometimes used as a lower racking arm

but primarily used for the tailing and guiding of the riser on a floating vessel

and as a general heavy lifting crane. Usually on the rig floor or suspended

slightly above the rig floor.

|

|

Figure 9: TTS Energy Smart Racker. Courtesy of TTS Energy.

|

An automated system of arms on a column that can be a fixed rotating (radial

pattern) machine or a traveling and rotating machine. Usually consists of a

single guide and single gripping hoist arm and has a primary function of

tripping the pipe without the intervention of human labor. Various modes and

versions exist with additional functionality including additional arms and tools

to facilitate stand-building off-line, riser tailing, riser tripping (stands of

riser), casing tripping (stands of casing) and integrated Iron Roughnecks. Three

fingerboard designs are common, the star fingerboard, where the column is a

fixed rotating design and the arms place the pipe in a radial fashion, the X-Y

fingerboard which mimics the traditional left-hand, right hand fingerboard with

the exception of each stand or a number of stands are locked in place with a

remotely controlled finger latch, or a parallel fingerboard where all the

fingers point towards well center and the racker travels in front of the set

back rotating 180 degrees to present the tubular stand at well center (this

system also latches like the X-Y fingerboard. These systems are prevalent on

high-spec offshore rigs and floating vessels where the lateral stand loads are

too high for typical manual operations by a derrickman.

|

↑

top

In a parallel racking system often the design will include a second racker on

the same track system. This is to facilitate redundancy as well as efficiency of

a rig that can build stands off-line while tripping in or out of the well.

↑

top

A mechanized or automated mud capturing device that also serves as a spray

protection for the crew when pulling a wet string tripping out of the hole.

Typically mounted on the drill floor where it is actuated to well center or on

an Iron Roughneck that brings it to well center during deployment. The captured

mud is returned to the pits, reducing waste and cost.

↑

top

A remote controlled or automated system for cleaning and lubricating the drill

pipe connections while tripping in the hole. Often times connected to an Iron

Roughneck.

↑

top

A process that incorporates machines to facilitate the construction of stands of

drillpipe away from the activities at well center. This may be done vertically

using one or more mousehole. This can also be done horizontally. This is done

independently, or in a parallel process, of normal drilling.

↑

top

|

|

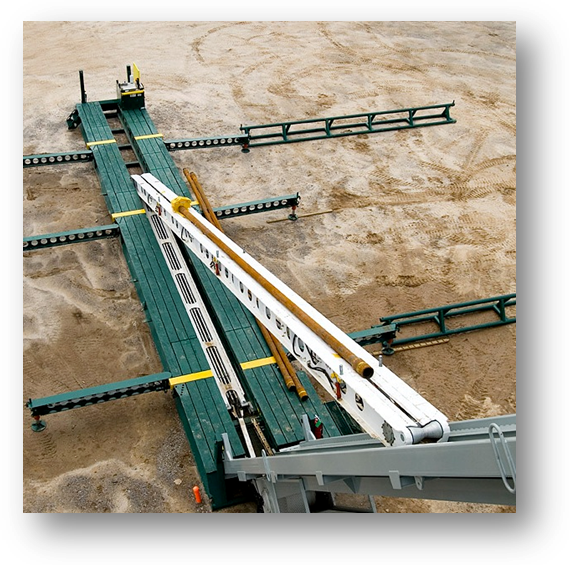

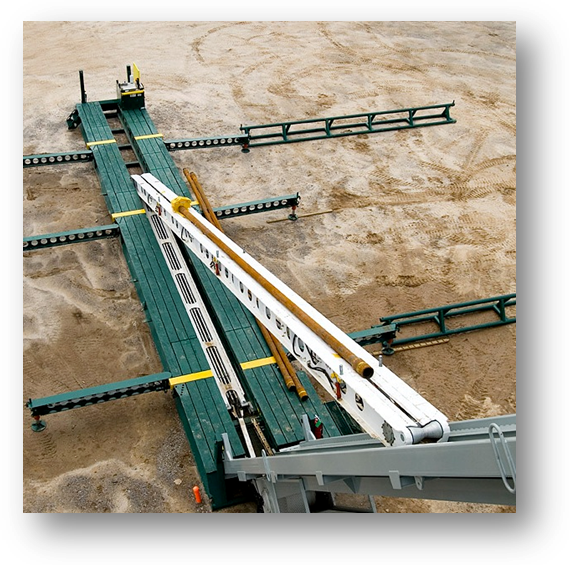

Figure 10: Canrig horizontal to vertical pipe

transfer arm. Courtesy of Canrig. |

Horizontal to Vertical Pipe Transfer Arm: A device designed to transition a

single tubular (and in a few cases whole stands) between a horizontal or angled

presentation and a vertical position in a mousehole or at well center. The

machine is usually integrated in to a V-door.

Pipehandling Boom: An arm-based machine that usually transitions drill pipe from

the horizontal to the vertical position in a single motion. It is usually

rotated around a fixed pivot point in the sub structure and is mostly used in

land rig applications. |

Figure 11: Courtesy of Precision Drilling

Oilfield Services Corp. |

↑

top

A derrick- or mast-fixed arm that is deployed solely for running casing. It

provides stability and control in the running of casing singles.

↑

top

An extending or telescoping arm with attachable heads, used to guide riser to

well center, manipulate tubulars or other items about the drill floor

↑

top

|

|

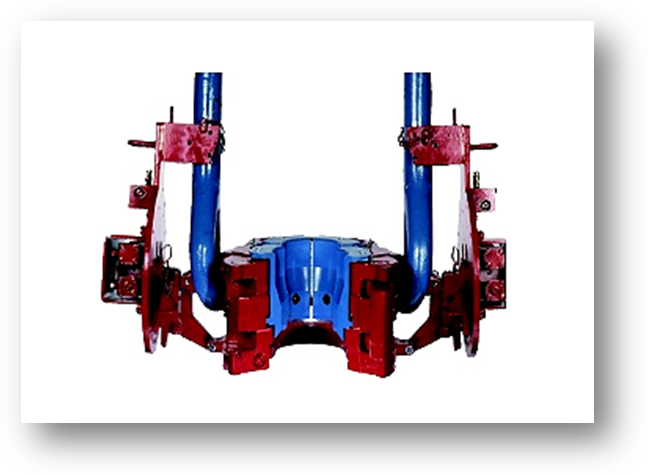

Figure 12a: NOV CRT-350 Casing Running Tool.

Courtesy of NOV.

Figure 12b: Photo of Volant Casing Running Tool (internal) CRTi courtesy Volant Products.

|

An adaptor that attaches to the top drive

eliminating floor tongs and manual handling of casing using the power and

rotation from the top drive. When connected to the top of the casing it is used

to spin in and make-up the connection of the casing accurately. This system may

also include a casing fill-up and/or casing circulation function. A floor based

method of holding adequate back up or a slip system is needed to react to the

torque in the string as the top drive is made up to the upper casing joint. |

↑

top

Horizontal Tubular Transfer: A horizontal or angled machine that transfers tubulars from the pipe deck/rack to the rig floor, often achieved with carts,

carriages, rollers, or belts.

Pipe Conveyor: A type of horizontal tubular transfer generally using a

continuous belt to convey the tubulars along the machine. Pipe Conveyors can

utilize only a belt that is loaded directly with a tubular handling crane, while

others also include side loading arms that transfer the pipe between the tubular

handling crane and belt.

Catwalk Machine: A horizontal pipe and/or riser handling system which transports tubulars and/or risers in and out of the rig floor. Typically these machines are

mounted at the drill floor elevation and are loaded with a deck crane or

dedicated tubular handling crane.

↑

top

A tubular handling machine is a pipe deck tubular handling arm, some of which

handle one joint of pipe at a time and some which handle bundles; however, these

are uniquely identified by the ability to handle tubulars on the pipe deck/rack

mechanically to connect to the pipe. These machines typically interface with

Pipe conveyors or pipe catwalk machines.

↑

top

The utility functions associated with a traditional mousehole, such as hoisting,

lowering, rotating, and grabbing or actuating with a slip assembly. Usually

associated with facilitating offline standbuilding activities.

↑

top

|

|

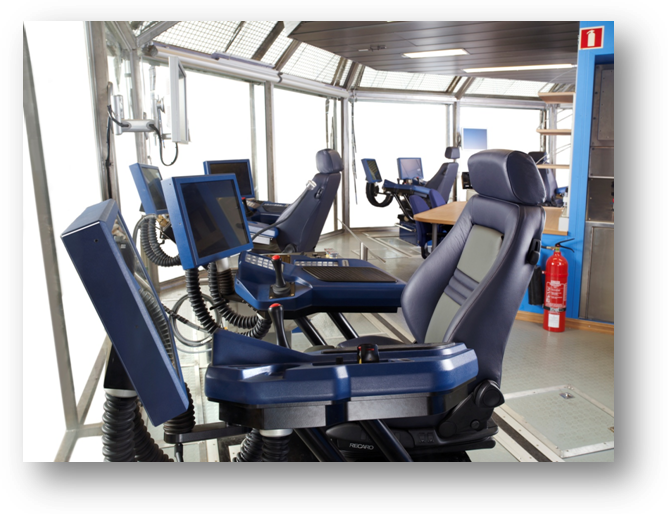

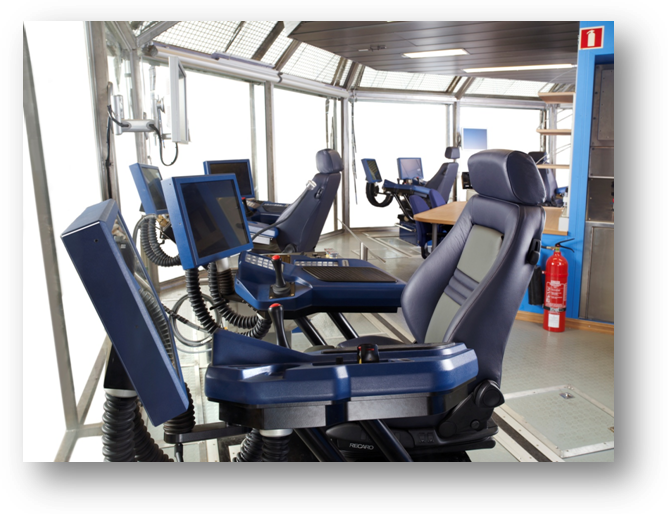

Figure 13: Courtesy of Canrig. |

An enclosure for remotely controlling equipment. Generally (but

not always) used to describe a Driller's cabin. The enclosure typically includes

both controls and instrumentation at an Operator's workstation. These cabins

have included controlled environment features such as heating and/or air

conditioning. Cabins commonly have windows to see operations and may also be

augmented with video displays for cameras showing areas difficult to see

directly. The enclosure may also be purged to maintain a safe level of flammable

gases or vapors by positive pressure or continuous flow. Integrated control

cabins also often have some method of communicating with the rig floor

integrated into the system. Often associated with an integrated control cabin is

a control chair(s) for the driller with additional stations for pipehandling

functions or redundancy. Ergonomics are also considered to help eliminate

operator fatigue. The amount of stations ranges from just the drillerís station

up to five stations on a multi-activity deepwater drillship. |

↑

top

A rig that utilizes a hydraulic powered hoisting system having long stroke

cylinders for pushing a sheave cluster and traveling assembly vertically. These

cylinders and sheave cluster are guided by a guide frame to allow the sheave

cluster to raise and lower the top drive and elevator during drilling

operations. The number of cylinders is determined by the load capacity. The

Cylinder Rig is an alternative system to the conventional drawworks, derrick,

and crown-mounted motion compensation systems. Since the hydraulic cylinders

carry the load, no derrick structure is required. However, the top drive will

need a guiding structure for travel and to absorb Torque.

↑

top

An additional device that can be installed on a passive heave compensator

system, such as a crown-mounted or drill string compensator. It is designed to

improve the performance and accuracy of the passive compensator during critical

sea bed landings and critical weight on bit requirements.

↑

top

|

|

Figure 14: NOV AHD-1250 Active Heave Drawworks.

Courtesy of NOV. |

A drawworks with an advanced controls system and additional power to provide the

heave compensation of the string on a floating vessel instead of the traditional

crown-mounted or drill-string motion compensation systems. Through use of the

reference frame system, the drawworks is activated via the control system

forwards and backwards to move the top drive, string, riser, etc. to maintain a

static position relative to the ocean floor.

Dual Active Heave Drawworks System: utilization of two active heave drawworks to

provide full load compensation without the need of a crown-mounted compensation

system and to increase the speed of the traveling assembly.

|

↑

top

A control arrangement to gradually phase the speed of all the active mud pumps

so that all the pistons are travelling in a synchronized fashion to smooth out

the average flow and pressure pulsations down the drillpipe.

↑

top

A remotely controlled, actuated, and/or reset high pressure mud pump discharge

relief valve. This system may be remotely operated or controlled electronically,

pneumatically, hydraulically or in some other manner.

↑

top

An electronic system for communicating critical control functions from the rig

floor to the BOP stack. The system incorporates two communicating controllers,

one receiving a command from the rig floor and translating that command to the

second controller, which verifies receipt of the command on the BOP stack, and

in turn converts the electrical signal into a hydraulic function. The reason for

using these systems is primarily in deepwater applications in excess of 4000

feet where response speed becomes a critical issue. The traditional methods of

using hydraulics/pneumatics to transfer this signal over long distances are no

longer sufficient. From four to seven thousand feet this is being carried out

with an electrical signal, however beyond 7000 feet, these systems are using

fiber optics to achieve sufficient response times. On some jackups, multiplex

controls are used to eliminate cable runs between the control system in the hull

and the cantilever based BOP stack.

Training:

GE Oil & Gas

↑

top

Signals transmitted in real-time (while drilling) from an instrument located

near the bottom of the drill string to a receiving monitor on the surface (a

surface-readout). Downhole telemetry may be transmitted via mud pulses (much as

sonar signals are transmitted through water), through electro-mechanical methods

(radio transmission) or via a wire within the drillpipe. Frequently, downhole

telemetry is employed in determining the drift angle and direction of a deviated

wellbore. The signal from the downhole tool to the surface is called an uplink.

(See measurement while drilling)

↑

top

|

|

Figure 15: NOV pipedeck operator/standbuilding chair. Courtesy

of NOV. |

|

↑

top

A PLC controlled flow distribution and remote valve controlled system to ensure

even flow distribution to all shakers including a start up procedure when flow

is increasing or a stop procedure when flow is decreasing.

↑

top

A system of a control unit and drilling mud mixing equipment where the drilling

mud mixing process can be automated, either to preset drilling mud properties or

to automatically control and mixing of drilling mud properties while drilling.

For instance, measurements of downhole and surface parameters can be used to

automatically adjust the mud conditions while drilling if well conditions

changes.

↑

top

A system with an automatic dustproof machine able to cut smaller sacks with

powder. It will separate powder into a feeding unit towards the mud mixer and

packaging into a waste material compacting unit. This slitter unit is often

integrated in a mud mixing system with lifting table for pallets and a PLC

controlled system with a local control panel. All this often delivered on a skid

for easy installation into the Mud Mix room/area.

↑

top

|

|

Figure 16: Omron Oilfield and Marine AC Drive (VFD).

Courtesy of Omron. |

An AC Drive is a system for controlling the rotational speed and/or torque of an

alternating current (AC) electric motor by controlling the frequency of the

electrical power supplied to the motor.

Training:

|

↑

top

Automatic Driller: A mechanism used to regulate the amount of weight on the bit

without the continual control by drilling personnel. Automatic drillers free the

driller from the sometimes tedious task of manipulating the drawworks brake to

maintain correct weight on the bit. It may also have the capability to control

weight within safe operating limits when more than one drilling parameter

changes at a time.

Training:

↑

top

|

Canrig

IADC

NOV

PETEX

Precision Drilling

Transocean

TTS Energy

*Other companies/individuals were invited to participate and chose not to.

1. National Oilwell Varco top drive

2 & 3. Aker Solutions

4. Transocean Discoverer Enterprise

5. National Oilwell Varco PS-30 Power Slips

6. National Oilwell Varco BX-4-75 Power Elevator

7. Canrig mechanized roughneck

8. TTS Energy Multifunctional Roughneck

9. TTS Energy Smart Racker

10. Canrig horizontal to vertical pipe transfer arm

11. Precision Drilling Oilfield Services Corp.

12. National Oilwell Varco CRT-350 Casing Running Tool

13. Canrig

14. National Oilwell Varco AHD-1250 Active Heave Drawworks

15. National Oilwell Varco pipedeck operator/standbuilding chair

16. Omron Oilfield and Marine AC Drive (VFD)

|